Georg Stronstorff, CEO Eurest and Johannes Reichenberger, ventopay CEO in an exclusive interview with Catering Management

In an exclusive interview, Catering Management spoke with Eurest CEO, Georg Stronstorff, and Johannes Reichenberger, CEO of ventopay. Both companies have a long-standing, trusting partnership that has had a lasting impact on the industry through successful joint projects and innovative approaches.

Mr. Stronstorff, Eurest is considered a pioneer in the digitization of communal catering and started with cashless payment and central operational control 20 years ago. What were the operational and economic considerations?

Mr. Stronstorff: 20 years ago, our customers’ POS was very heterogeneous, each customer had a different cash register system. Call it luck or coincidence, we started on a small scale – with around 40 restaurants – to build a uniform POS system. So we recognized early on how important a uniform system is. Looking back, it was an enormous benefit to have built up a partnership with ventopay.

Whether it was for the central administration of data, for the introduction of an inventory management system, central and automated reporting or operational control. That was and is the advantage of ventopay, always finding a common solution for all these challenges.

Mr. Reichenberger, what role did ventopay play in the adaptation and further development?

Mr. Reichenberger: Eurest recognized the relevance of digital transformation very early on. Payment optimization and the importance of data in the operational context quickly brought operational added value. 20 years ago, the integration of employee ID cards and electronic payment media was still in its infancy. Together we were able to start here and make the payment process for the guest quick, secure and easy using the latest technology. Little by little, an overall digital platform was developed and great innovations implemented. For example, we equipped Europe’s largest canteen with a payment and subsidy solution via bank card.

Our philosophy is that we are developing from the POS to the EOS (Environment of Service). In an EOS, the needs of the guests on the one hand and the needs of the operators on the other are perfectly brought into focus – we see ourselves as experts who support digital transformation and bring trends from research into practice.

Mr. Stronstorff: Since the beginning, the data issue has developed massively and we have not yet reached the maximum. Today, I think we are the only country in the group that can compare prices with the previous year in 98% of our 100 or so restaurants at the touch of a button, analyze prices for each product, or create lists of bestsellers and loser sellers. We take into account all of our customers’ different circumstances and still have a uniform system. Without the early recognition of data relevance and a partner at our side who has accompanied and challenged us along the way, we would not be where we are today.

Homogeneous data and digitization are abstract concepts. Can you give us an example of the added value?

Mr. Stronstorff: By standardizing our POS system, we have simplified our processes considerably and created a basis for innovation. Especially during the COVID-19 pandemic, the central digital platform, which is more than “just” a POS system, enabled extremely rapid adaptation. We were able to quickly implement digital ordering systems, agree with our customers that subsidies can also be accessed at home and deliver the order to their homes. This enabled us to pursue paths that were previously unimaginable in community catering, as our business has been constant over the last 20 years.

As a provider with whom Eurest has embarked on this path together, how does ventopay enable this integration?

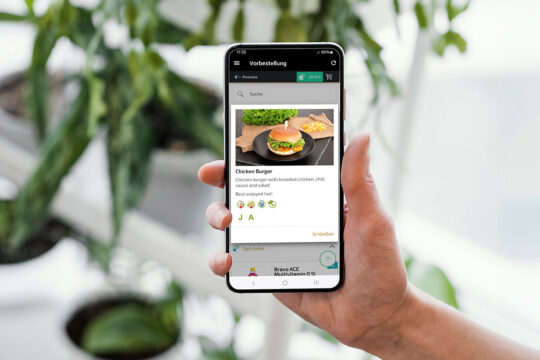

Mr. Reichenberger: To enable integrations, you need – to stay in gastronomic parlance – a very important ingredient: a partnership. One thing is to offer an excellent system that offers all these possibilities. The other is that it must also be accepted – only then does it become a recipe for success. The rest is technical craftsmanship with which we have developed over the past 20 years from the POS to the leading digital platform. The system includes everything from the cash register to the payment system, the vending sector, smart fridges, customer loyalty solutions with apps, web shops and AI-based infotainment. All solutions access a uniform data platform. This means that solutions such as orders to the home office can be implemented in the shortest possible time.

Mr. Stronstorff: An example on the subject of partnership. Siemens wanted to integrate a health tracker into the app. The guests should be able to see what ingredients and calories were in the lunch. This may look simple at the beginning, before many building blocks are added in the project phase and it may not work straight away in the first step. It is then up to the partnership to take these development steps and overcome hurdles together. Both sides need to be challenged and develop their systems further – in this respect we have a good partner in ventopay.

Where do you currently see the challenges, apart from driving digitalization forward?

Mr. Stronstorff: I think the biggest challenge for the industry is the issue of personnel and the flexibility associated with it. Automation, e.g. optical food recognition, certainly plays a key role here. In this area, we can certainly reduce staff and use them for other tasks. However, the human factor is always needed in our business.

Cashiers in particular are crucial – they know our guests and communicate with them, but thanks to automatic food recognition and payment, for example, we no longer need 5 cash registers with cashiers. We want to use digitalization to relieve our employees, for example through automated invoice creation, automated reporting, automatic goods ordering, production planning, etc. – in order to have more time for and with the guests.

Mr. Reichenberger: As technicians, we have been able to learn a lot over the last two decades. We have now understood that all gastronomic processes are very strongly linked to emotions at the end of the day. Accordingly, solutions are needed that promote this emotionality.

How can the required flexibility be achieved with a shortage of staff?

Mr. Stronstorff: There are days when sales have been lower, for example due to working from home. We have to consider offering a different service, such as pre-ordering and table service, in order to minimize the overall effort and at the same time increase the service for the guest. The systems have to support this and also allow the flexibility to switch back. This minimizes production effort and food waste and helps with personnel planning. There is still a lot to be implemented and the platform is crucial in this.

Mr. Reichenberger: Absolutely. And the platform is ready to go.

A “just in time” solution is very fast, even for the software industry. How do we achieve this?

Mr. Reichenberger: It’s about being very close to the market and our partners. Communication is incredibly important. With our efficient R&D, we can also react very quickly to new market and innovation ideas. We employ more than 1/3 of the people in the company in research and development and are therefore very quick to implement solutions that create real added value. We also work very closely with Universities of Applied Sciences and university institutions.

Our focus is clearly on communal catering and the large kitchens of the world.

We always try to be one step ahead, which entails the risk of the odd empty kilometer.

For example, we are already looking at the checkout of the future – the camera-based checkout is almost old hat again. We are thinking one step ahead. What will come next and we hope, of course, that our ideas will meet the needs and we can offer ready-made solutions when the market is ready.

You both mentioned the human factor earlier. How can digital change be achieved?

Mr. Stronstorff: We always try to reach out to people and show them the added value for their work. Change is often difficult at first. When optical food recognition was introduced, people were afraid of being controlled and losing their jobs. So it’s a sensitive issue because we need highly motivated and committed employees. It’s best when digital innovation works in a company and colleagues talk to each other. That’s how things get rolling, fears give way and curiosity and advantages take their place. That was also the case with automatic accounting. The goal must be to reduce administration and give more space to our core business.

Mr. Reichenberger: A lot has already been said. The term digitization does not go far enough; I would like to replace it with digital transformation, in which processes change for the better for people. The added value of digital transformation must be recognized by decision-makers, plant managers and managers. The reduction in work and effort must be the top priority.

We talked about the future earlier. Where do you see the future of digitalization in communal catering?

Mr. Stronstorff: Corona has brought about a big change, for example working from home. The number of guests is more volatile, which makes production planning significantly more difficult. Before Corona, experienced managers were able to estimate very precisely which dishes would be chosen and in what quantities. Today, planning is much more difficult. We started a great joint project with AI-based production planning. The first evaluations that I have seen are already very accurate in terms of prediction accuracy. In my opinion, this result, at this early stage of the research project, is groundbreaking. We have great potential here for planning and, above all, for reducing food waste.

This is our biggest issue in the catering industry. Every kilo of meat, every kilo of vegetables has an extreme carbon footprint. Everything we save in production has a very large leverage effect on reducing food waste.

That’s why we said right away that we want to get involved. It’s important to always get new ideas from a partner and to be able to say, OK, this is the right path that we want to follow.

As the market leader in the area of fresh cuisine, we feel obliged to the next generations and our environment and want to have a positive impact on people’s well-being through our meaningful actions and innovation.

Mr. Reichenberger: I can only agree with you. In my view, forecasting is a key future factor for sustainability and profitability. Here, too, we have thought a step further together with the experts from Eurest – but I don’t want to give too much away about it yet, as we are currently still in the research stage. But one thing is certain: AI-based forecasting offers many, as yet unimagined possibilities along the entire production chain.

It is a matter close to my heart to reduce food waste in the food industry. Around 40% of all food produced in the world is not consumed. If we can use technology to help reduce food waste, then we should definitely do so.

Eurest is represented throughout Austria with around 100 locations and offers for community catering, schools as well as the health and care sector. You can find more information at Eurest | Home

Inquire now without obligation!

Contact person search

Technical support team

If you have technical problems, our support team will help you quickly and easily:

AUT: +43 5 7236 – 400

GER: +49 201 874697 – 65

CH: +43 5 7236 – 400

SHARE ON